Motek and Pearl started their close partnership in 2014 when Motek chose to run their business on Pearl’s SAP based template solution. In 2017, Motek was the first retail business in Europe on S/4, this upgrade was delivered by Pearl in only 8 weeks. In Autumn 2019 the S/4-solution required an upgrade to version 1809 and once again Pearl was there to help.

– Our experience is that the upgrade has gone much better than we had expected. The programs which SAP delivered, have worked, and Pearl have assisted and put in an effort to get the solution in place. From commencing the project, it was less than 2 months until we were up and running on a new version. For us, it is very important that we have a partner who takes overall responsibility for both database operations and the SAP program itself. And Pearl does this, says Ketil Greve Aubert, Head of IT at Motek.

In Autumn 2019, Motek announced that they were moving into temporary premises at Frogner. This was due to the demolition and modernisation of their existing warehouse in Oslo. Due to this, Motek contacted Pearl, requesting a new storage system that could support their existing storage processes and needs, while simultaneously providing them with a high degree of automation and efficiency.

During the same period, the implementation of an Embedded Extended Warehouse Management (EWM) solution on S/4 HANA was started, a complete storage solution provided by Pearl with direct integration to AutoStore. This was a demanding project as the implementation was to take place in parallel with the relocation process. The close partnership between Pearl and Motek was crucial in ensuring a successful delivery.

I am very satisfied with Pearl as a partner on Motek's EWM and relocation project. We get great resources on the project, and you are quick to take action – together with us - through thick and thin.This has given us a sense of security during the completion of a demanding project.

Jørn Sæbø, CFO and Logistics Director at Motek.

About Motek

Motek is a large vendor of tools and fasteners for the professional building and construction industry. The company imports strong brands such as Hilti, Festool and Stanley Bostitch. In addition, they have their own brand within fasteners and sealants.

Motek was founded in 1954 when they acquired the Hilti Agency. They are nationwide and employ more than 320 full-time equivalents. This is represented by 120 sales representatives out on construction sites, direct deliveries, customer service, 30 stores and e-commerce via motek.no.

About the solution - Embedded Warehouse Management at Motek

SAP S/4 HANA came on the market in 2016 and Embedded EWM was introduced at the same time. By having an integrated EWM solution as a built-in application component in S/4 HANA, you have a far more cost-effective way to manage and optimize your storage operations. This provides a number of advantages based on a more integrated and efficient inventory management model.

Embedded EWM is a cost-effective solution that provides optimized inventory management and the ability to automate processes. In order to maintain market position and promote further development in a global market, EWM was the right choice for Motek. Embedded EWM was a natural choice based on their already existing SAP S/4 HANA solution. Motek also chose to use AutoStore as part of their storage solution to streamline storage capacity.

Expertise and experience with EWM

Having implemented a similar solution, also with integration to AutoStore at Fjellsport a few months earlier, Pearl had the necessary expertise to deliver a good product. Komplett’s EWM solution with AutoStore integration has also been an experience builder for Pearl, along with other decentralized EWM projects. Motek's solution was built on Pearl's high level of expertise and experience with EWM.

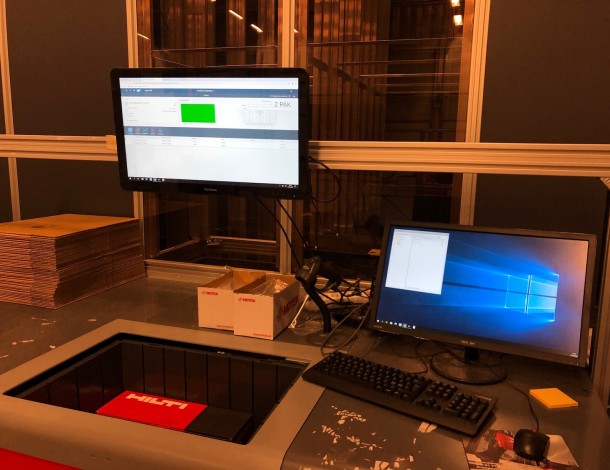

Motek had AutoStore installed at Frogner, where Pearl took responsibility for creating the link between AutoStore and EWM. Items which did not fit into AutoStore were placed on shelves with good marking of locations and zones. The all-in-one solution covers communication between AutoStore and EWM, as well as smart and easy-to-use Apps for all processes in the manual part of the storage facility, using the Fiori interface.

– Pearl has the belief and experience that smart solutions can often be reused by several customers, tailored to each client's specific needs. This often limits the complexity of the project phase and shortens the time to Go-Live (deployment of the solution in production), says CEO at Pearl Group, Geir Thoresen.

This was experienced on the Motek EWM project, which commenced in late October 2019 and in January 2020 goods reception moved its first pallet of goods into the new warehouse.

– Pearl's previous experience with EWM implementations and continued investment in EWM projects to further build expertise and experience, has benefited both Motek and other customers. Pearl has several other clients who will implement EWM, and we look forward to using this knowledge and experience to optimize more storage solutions. It is crucial for organizations to evaluate the best options for their own individual purposes. With the flexibility to deploy EWM in multiple ways, SAP has further enhanced the value of one of the most popular inventory management solutions available today, says Thoresen.

Contact us for further information

Should you need help in choosing the right alternative for your needs, we are here to help guide you through the process and ensure the best fit for your business. If you are to meet the increased competition in the market and the requirements for efficiency in logistics and warehousing, this is the future solution for you. Feel free to contact us to talk more about EWM, both integrated and decentralized, as we are the consultancy firm with the most extensive expertise in the field in Norway.